7 Must-Have Features for Your Food Trailer Design

food trailer features Discover the essential features that will make your food trailer efficient, profitable, and compliant with health regulations. These design elements are crucial for any successful mobile food business.

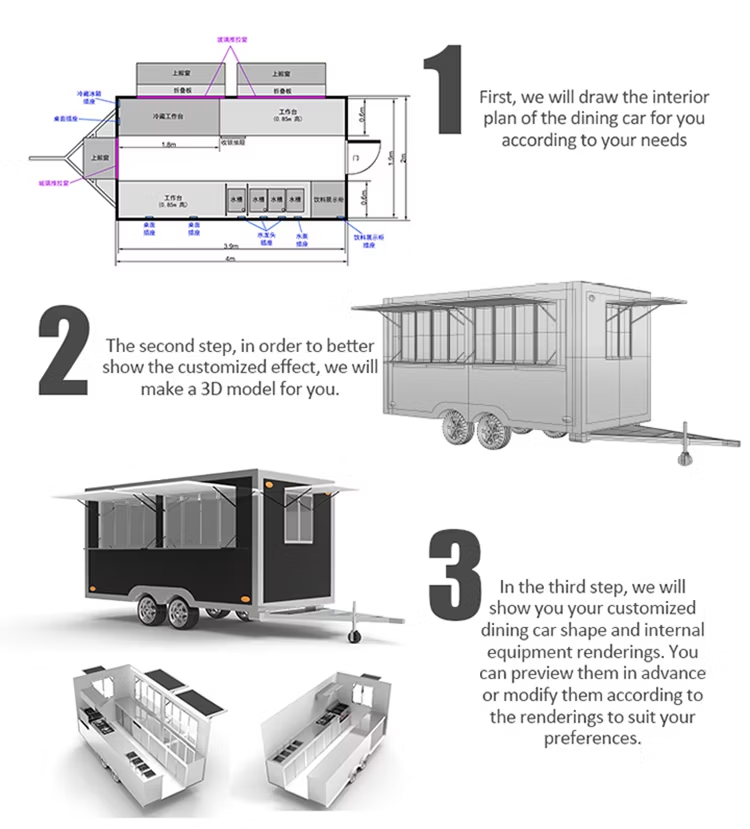

Starting a food trailer business requires careful planning and smart design choices. The right features can make the difference between a profitable venture and a costly mistake. Whether you’re launching your first mobile kitchen or upgrading an existing setup, these seven essential features will help you create a functional, efficient, and successful food trailer operation.

1. Commercial-Grade Ventilation System

A proper ventilation system is absolutely critical for any food trailer operation. Without adequate airflow, your mobile kitchen becomes a hot, smoky, and potentially dangerous workspace that violates health codes and creates uncomfortable working conditions.

Your ventilation system should include a commercial exhaust hood that captures grease, smoke, and odors at their source. The hood must be sized appropriately for your cooking equipment and positioned to maximize efficiency. Most health departments require exhaust hoods to extend at least six inches beyond the cooking surface on all sides. food trailer features

Fire suppression systems integrated with your ventilation are often mandatory. These systems automatically deploy fire-retardant chemicals when temperatures exceed safe levels, protecting your investment and ensuring operator safety. The exhaust fan should be powerful enough to create negative pressure inside the trailer, preventing smoke and odors from escaping through service windows.

Make-up air systems work alongside exhaust fans to replace the air being removed. Without proper make-up air, your trailer will struggle to maintain comfortable temperatures and may not meet code requirements. Consider installing variable speed controls to adjust ventilation based on cooking intensity and weather conditions.

Regular maintenance of your ventilation system is essential. Grease buildup in ductwork creates fire hazards and reduces system efficiency. Plan for professional cleaning and inspection schedules to keep your system operating safely and effectively.

2. Efficient Kitchen Layout and Workflow Design

Space is precious in a food trailer, making efficient layout design crucial for productivity and profitability. Every square inch must serve a purpose, and the workflow should minimize unnecessary movement while maximizing output. food trailer features

The classic kitchen triangle concept applies to food trailers but requires adaptation for the linear space constraints. Position your prep area, cooking station, and service window to create a logical flow from ingredient storage through preparation, cooking, and final service.

Consider implementing a galley-style layout with equipment and storage along both walls, leaving a central aisle for movement. This design maximizes available space while providing easy access to all work areas. The aisle should be at least 36 inches wide to accommodate safe movement of staff and equipment.

Vertical storage solutions help maximize your limited space. Install shelving, hooks, and magnetic strips to keep frequently used tools and ingredients within easy reach. Under-counter storage should be organized with pull-out drawers and bins for quick access to supplies.

Plan your electrical and plumbing rough-ins during the design phase to avoid costly modifications later. Position outlets and water connections where you’ll need them most, and include extra capacity for future equipment additions or changes to your menu.

Test your layout design by walking through typical service scenarios. Time how long it takes to prepare your most popular items and identify any bottlenecks or inefficiencies. Small adjustments during the design phase can save significant time and frustration during actual operations.

3. Adequate Refrigeration and Food Storage

Proper food storage is non-negotiable for food safety and regulatory compliance. Your refrigeration system must maintain consistent temperatures while being energy-efficient enough for mobile operations.

Commercial-grade refrigeration units designed for mobile applications handle the vibration and temperature fluctuations that come with trailer operations. Standard residential units will fail quickly under these conditions and may not meet health department requirements.

Plan for multiple temperature zones to accommodate different food types. You’ll likely need standard refrigeration for most ingredients, freezer space for proteins and frozen items, and possibly a separate prep cooler for items being actively used during service.

Reach-in coolers positioned below work surfaces provide convenient access while saving space. These units should have solid doors rather than glass to improve energy efficiency and reduce heat gain in your already warm kitchen environment.

Dry storage areas must be sealed against pests and moisture while remaining easily accessible. Use food-grade containers with tight-fitting lids and implement a first-in-first-out rotation system to maintain ingredient freshness.

Consider installing temperature monitoring systems that alert you to any cooling system failures. A refrigeration breakdown can destroy your entire inventory and force you to close until repairs are completed. Remote monitoring systems can send alerts to your phone, allowing you to respond quickly to problems.

4. Reliable Water and Waste Management Systems

Water systems in food trailers must provide adequate pressure and volume for cooking, cleaning, and hand washing while managing waste water in compliance with local regulations.

Fresh water tanks should provide enough capacity for a full day of operations, including cooking, cleaning, and hand washing. Most successful operations require between 40-100 gallons of fresh water capacity, depending on menu complexity and service volume.

Water pumps must maintain consistent pressure throughout your plumbing system. Variable speed pumps adjust automatically to demand, providing steady pressure while conserving battery power. Include a pressure tank to reduce pump cycling and extend equipment life.

Hot water systems should provide adequate temperature and volume for food preparation and sanitizing. Tankless water heaters work well in trailers because they save space and provide unlimited hot water on demand, though they require adequate gas supply and proper venting.

Gray water tanks must accommodate all waste water from sinks, prep areas, and equipment cleaning. Size your gray water tank larger than your fresh water tank to account for cleaning chemicals and food waste that increase waste volume.

Install grease traps where required by local regulations. These devices separate fats, oils, and grease from waste water before it enters your gray water tank, preventing clogs and environmental violations. Regular cleaning and maintenance of grease traps is essential for proper operation.

Consider installing water filtration systems to improve taste and protect equipment from mineral buildup. This is especially important if you’ll be operating in areas with hard water or questionable water quality.

5. Sufficient Electrical Power and Distribution

Modern food trailers require substantial electrical power for refrigeration, cooking equipment, lighting, and point-of-sale systems. Your electrical system must be reliable, safe, and adequate for both current needs and future expansion.

Shore power connections allow you to plug into standard electrical service when available, providing the most cost-effective power source. Install a weatherproof electrical panel with appropriate breakers and GFCI protection for all outlets in wet areas.

Generator systems provide power independence but require careful selection based on your total electrical load. Calculate the starting and running watts for all equipment to ensure your generator can handle peak demands. Diesel generators typically offer better fuel efficiency and longer life than gasoline units.

Battery systems can supplement generator power for low-demand periods or provide backup power for critical systems like refrigeration. Lithium batteries offer longer life and better performance than traditional lead-acid batteries but require higher initial investment.

Solar panels can reduce generator runtime and fuel costs while providing quiet, clean power for lighting and small appliances. Size your solar array based on available roof space and daily power consumption patterns.

Install adequate outlets throughout your trailer to avoid extension cord hazards. Include USB charging stations for staff devices and customer convenience. Consider installing inverters to provide standard 120V power from your battery system for small appliances and electronics.

Electrical safety is paramount in the confined space of a food trailer. All electrical work should be performed by licensed electricians familiar with mobile food service requirements. Regular inspection and maintenance of electrical systems prevents dangerous failures and ensures code compliance.

6. Durable and Easy-to-Clean Surfaces

Food service environments demand surfaces that withstand heavy use, frequent cleaning, and sanitizing chemicals while maintaining their appearance and functionality over time.

Stainless steel remains the gold standard for food service applications. It resists corrosion, doesn’t harbor bacteria, and maintains its appearance with proper care. Use 16-gauge or heavier stainless steel for work surfaces and backsplashes to prevent denting and warping.

Flooring must provide slip resistance, easy cleaning, and durability under heavy foot traffic. Commercial vinyl flooring designed for food service offers good performance at reasonable cost. Avoid seams where possible, and use welded seams where joints are necessary to prevent moisture and bacteria infiltration.

Wall surfaces should be smooth, non-porous, and light-colored to show cleanliness and provide good lighting reflection. FRP (fiberglass reinforced plastic) panels offer excellent durability and easy cleaning at lower cost than stainless steel.

Cove bases eliminate sharp corners where dirt and bacteria can accumulate. These curved transitions between floors and walls make cleaning easier and more effective while meeting health department requirements.

Choose hardware and fixtures that resist corrosion and frequent sanitizing. Stainless steel faucets, handles, and fasteners will maintain their appearance and function longer than plated or painted alternatives.

Avoid porous materials like wood or unsealed concrete that can harbor bacteria and absorb odors. If wood elements are desired for aesthetic reasons, ensure they’re properly sealed and located away from food preparation areas.

7. Strategic Service Window and Customer Interface Design

Your service window is the primary interface between your business and customers. Its design affects operational efficiency, customer experience, and sales volume.

Window size and positioning should accommodate your service style and menu complexity. Larger windows provide better customer interaction and allow for more elaborate food presentation, while smaller windows may be more practical for simple grab-and-go operations.

Serving counters should be at comfortable heights for both staff and customers. Standard counter height is 36 inches, but consider your staff’s average height and typical customer demographics when finalizing dimensions.

Weather protection keeps your service area functional in various conditions. Awnings or canopies protect customers and staff from sun and rain while extending your effective service area. Removable or retractable options provide flexibility for different locations and weather conditions.

Menu boards should be clearly visible and easy to read from a distance. Digital displays offer flexibility for menu changes and specials but require additional power and weather protection. Traditional boards are more reliable but less flexible for frequent changes.

Point-of-sale systems streamline ordering and payment processing while providing valuable sales data. Choose systems designed for mobile operations with reliable wireless connectivity and battery backup capabilities.

Storage for condiments, napkins, and utensils should be easily accessible to customers without creating clutter or safety hazards. Consider installing dispensers that protect supplies from weather while allowing easy access.

Lighting around the service area improves visibility and creates an inviting atmosphere for evening operations. LED fixtures provide bright, energy-efficient lighting that works well with battery or generator power systems.

Planning Your Food Trailer Investment

Implementing these essential features requires careful planning and adequate budget allocation. Each feature contributes to operational efficiency, regulatory compliance, and long-term profitability.

Work with experienced food trailer manufacturers who understand local health codes and operational requirements. FDA Food Code guidelines provide the foundation for most local regulations, but specific requirements vary by jurisdiction.

Consider future expansion and menu changes when designing your trailer. Installing additional electrical capacity or plumbing rough-ins during initial construction costs less than retrofitting later. Plan for equipment upgrades and operational changes that may occur as your business grows.

Quality components cost more initially but provide better long-term value through reduced maintenance, longer life, and better performance. Commercial-grade equipment designed for mobile applications will serve you better than residential or stationary commercial units.

Regular maintenance schedules keep all systems operating efficiently and prevent costly breakdowns during peak business periods. Establish relationships with service providers in your operating area before you need emergency repairs.

The Mobile Food Association offers resources and networking opportunities for food truck and trailer operators. Connecting with experienced operators provides valuable insights into practical design decisions and operational challenges.

Maximizing Your Food Trailer Success

These seven essential features form the foundation of a successful food trailer operation. Proper ventilation ensures safety and compliance, while efficient layout maximizes productivity in limited space. Adequate refrigeration and storage maintain food quality and safety, while reliable utilities keep operations running smoothly.

Durable, cleanable surfaces reduce maintenance costs and support food safety protocols. A well-designed service interface creates positive customer experiences that drive repeat business and referrals.

Investing in quality features during initial construction pays dividends through reduced operating costs, fewer repairs, and better customer satisfaction. Take time to research options, consult with experienced operators, and work with reputable manufacturers who understand the unique demands of mobile food service.

Your food trailer represents a significant investment in your entrepreneurial future. By incorporating these essential features, you’ll create a mobile kitchen capable of delivering consistent, profitable operations while meeting the highest standards for food safety and customer service.

No products in the cart.

No products in the cart.