Food Trailer Maintenance: Essential Tips and Checklist

food trailer maintenance checklist Proper maintenance of your food trailer ensures food safety, extends equipment lifespan, and prevents costly breakdowns. This comprehensive guide covers daily, weekly, and monthly maintenance tasks every food trailer owner should follow.

Why Food Trailer Maintenance Matters

Running a successful food trailer business requires more than just great recipes and customer service. Regular maintenance protects your investment, ensures compliance with health regulations, and prevents unexpected breakdowns that can cost you thousands in lost revenue.

A well-maintained food trailer operates more efficiently, consumes less fuel, and provides a safer working environment for your staff. Most importantly, proper maintenance helps you avoid health department violations that could shut down your business temporarily or permanently.

Daily Maintenance Tasks

Start each day with these essential checks to ensure your food trailer operates safely and efficiently throughout service hours.

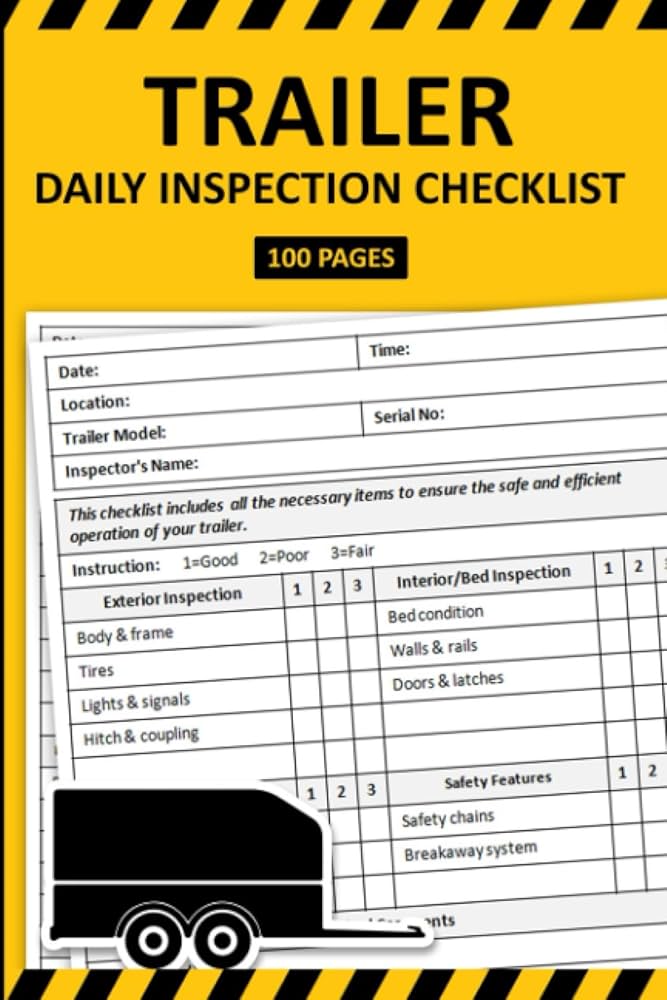

Exterior Inspection

- Check tire pressure and look for signs of wear or damage

- Inspect trailer hitch, safety chains, and electrical connections

- Examine exterior panels for dents, rust, or loose fasteners

- Test all exterior lights including brake lights and turn signals

- Verify that the license plate and registration are current and visible

Interior Systems Check

Before firing up your equipment, conduct a thorough interior inspection. Check that all electrical connections are secure and free from corrosion. Test your generator or shore power connection to ensure stable power supply throughout the day.

Inspect your propane system by checking tank levels, connections, and looking for any signs of leaks. Use soapy water on connections to identify potential gas leaks before they become dangerous.

Equipment Functionality

- Test all cooking equipment before heating up

- Verify that refrigeration units maintain proper temperatures

- Check water pump pressure and tank levels

- Ensure exhaust fans and ventilation systems operate correctly

- Test fire suppression system indicators

Weekly Deep Cleaning and Maintenance

Weekly maintenance goes beyond daily cleaning to address areas that accumulate grease, debris, and wear over time. food trailer maintenance checklist

Ventilation System Maintenance

Your exhaust hood and ventilation system work harder than any other component in your food trailer. Remove and clean hood filters thoroughly with degreasing solution. Inspect the exhaust fan for grease buildup and clean blades carefully.

Check that your fire suppression system nozzles are clear of grease and debris. Test the manual pull station to ensure it activates properly, but avoid triggering the actual suppression system during routine testing.

Plumbing System Care

Flush your water system weekly to prevent bacterial growth and mineral buildup. Clean and sanitize your fresh water tank using food-grade sanitizing solution. Check all faucets, connections, and the water pump for leaks or unusual noises.

Empty and clean your grey water tank completely. Inspect the tank and drainage system for clogs or damage that could cause backups during busy service periods.

Electrical System Inspection

- Check all GFCI outlets for proper function

- Inspect electrical panels for signs of overheating or corrosion

- Test generator under load conditions

- Examine extension cords and power cables for damage

- Verify that circuit breakers operate correctly

Monthly Comprehensive Maintenance

Monthly maintenance addresses mechanical systems and components that require less frequent but more thorough attention.

Trailer Mechanical Systems

Inspect your trailer’s suspension system, including springs, shocks, and mounting hardware. Look for signs of excessive wear, rust, or damage that could affect towing safety or stability.

Check wheel bearings by lifting each wheel and testing for excessive play or grinding noises when rotated. Properly maintained bearings prevent costly axle damage and dangerous wheel failures.

Appliance Deep Maintenance

Schedule monthly deep cleaning for all major appliances. This includes descaling your coffee machines, deep cleaning fryer oil systems, and calibrating thermostats on cooking equipment.

Inspect refrigeration coils and clean them thoroughly to maintain efficiency. Check door seals and gaskets for tears or gaps that allow cold air to escape, increasing energy consumption and reducing food safety.

Propane System Service

Have your propane system professionally inspected monthly during peak season. This includes checking regulator function, testing safety shutoff valves, and verifying that all connections meet current safety standards.

Keep detailed records of propane tank certifications and replacement dates. Expired tanks can fail inspection and shut down your operation unexpectedly.

Seasonal Maintenance Requirements

Seasonal changes require specific maintenance attention to protect your food trailer from weather-related damage and ensure reliable operation year-round.

Winter Preparation

Cold weather presents unique challenges for food trailer operation. Insulate exposed water lines to prevent freezing, and consider installing tank heaters in extremely cold climates.

Switch to winter-grade lubricants for mechanical components and ensure your generator can handle increased heating loads. Stock extra propane tanks since consumption increases significantly in cold weather.

Summer Readiness

Hot weather puts extra strain on refrigeration and ventilation systems. Clean condenser coils more frequently and ensure adequate airflow around cooling equipment.

Check that your exhaust system can handle increased cooking loads during busy summer festival season. Consider upgrading ventilation capacity if you frequently experience overheating issues.

Essential Maintenance Tools and Supplies

Maintain a well-stocked toolkit specifically for your food trailer maintenance needs. Basic tools should include adjustable wrenches, screwdrivers, electrical multimeter, and tire pressure gauge.

Stock replacement parts for commonly failing components like fuses, light bulbs, gaskets, and filters. Having these items on hand prevents minor issues from becoming major problems during busy service periods. food trailer maintenance checklist

Cleaning and Sanitizing Supplies

- Food-grade sanitizing solutions

- Degreasing cleaners for exhaust systems

- Stainless steel cleaners and polishes

- Drain cleaning chemicals

- Glass cleaners for windows and display cases

Record Keeping and Documentation

Maintain detailed maintenance records for insurance, warranty, and regulatory compliance purposes. Document all repairs, replacements, and service dates with receipts and photos when appropriate.

Create a maintenance log that travels with your trailer, allowing any team member to quickly identify when specific tasks were last completed. This prevents duplicate work and ensures nothing gets overlooked during busy periods.

Regulatory Compliance Documentation

Keep copies of all required certifications including propane system inspections, fire suppression service records, and electrical system certifications. Many jurisdictions require these documents for permit renewals and health department inspections.

According to the FDA Food Code, mobile food units must maintain equipment in good repair and proper working condition at all times.

Common Maintenance Mistakes to Avoid

Many food trailer owners make costly mistakes that could be easily avoided with proper knowledge and planning.

Neglecting Preventive Maintenance

Waiting until equipment fails before performing maintenance costs significantly more than preventive care. A failed refrigeration compressor during peak season can cost thousands in lost revenue plus emergency repair fees.

Establish and stick to your maintenance schedule regardless of how busy your operation becomes. The short-term inconvenience of scheduled maintenance prevents much larger disruptions later.

Using Incorrect Cleaning Products

Not all cleaning products are appropriate for food service equipment. Avoid harsh chemicals that can damage stainless steel surfaces or leave residues that contaminate food.

Always use food-grade cleaning and sanitizing products, and follow manufacturer instructions for proper dilution ratios and contact times.

When to Call Professional Service

While many maintenance tasks can be performed by trailer owners, some require professional expertise for safety and warranty compliance.

Electrical System Work

Any electrical work beyond basic bulb replacement should be performed by licensed electricians familiar with mobile food service requirements. Improper electrical work creates fire hazards and can void insurance coverage.

Gas System Repairs

Propane system repairs and modifications must be performed by certified technicians. The National Fire Protection Association sets strict standards for LP-gas installations in mobile food service units.

Cost-Effective Maintenance Strategies

Smart maintenance planning helps control costs while ensuring reliable operation. Group similar tasks together to maximize efficiency and minimize downtime.

Establish relationships with reliable service providers who understand food trailer operations. Many shops offer discounted rates for regular customers and can prioritize emergency repairs when needed.

Bulk Purchasing and Inventory Management

Buy commonly needed supplies in bulk to reduce per-unit costs. However, avoid overstocking perishable items like filters and gaskets that can deteriorate over time.

Track usage patterns to optimize inventory levels and prevent stockouts of critical maintenance supplies during peak operating seasons.

Emergency Preparedness

Despite the best maintenance efforts, equipment failures can occur at the worst possible times. Develop contingency plans for common failure scenarios.

Maintain relationships with equipment rental companies that can provide temporary replacements for critical systems like generators or refrigeration units. Know their availability and pricing before you need emergency service.

Mobile Repair Services

Identify mobile repair services in your regular operating areas. Many technicians specialize in food service equipment and can perform repairs on-site, minimizing lost operating time.

Keep contact information for emergency services easily accessible to all team members who might need to coordinate repairs during your absence.

Conclusion

Consistent food trailer maintenance protects your investment, ensures food safety compliance, and prevents costly emergency repairs. By following this comprehensive maintenance checklist and establishing regular service schedules, you can maximize your trailer’s lifespan and minimize unexpected downtime.

Remember that maintenance costs are a normal part of operating any food service business. Budget appropriately for both routine maintenance and unexpected repairs to avoid financial strain when issues arise.

The time and money invested in proper maintenance pays dividends through reliable operation, lower long-term costs, and the peace of mind that comes from knowing your equipment will perform when you need it most.

No products in the cart.

No products in the cart.