Custom Food Trailer Builds: What to Expect

food trailer construction Understanding the custom food trailer construction process helps entrepreneurs make informed decisions and set realistic expectations for their mobile food business venture. This comprehensive guide covers every aspect of building a custom food trailer from initial planning to final delivery.

Initial Consultation and Design Phase

The custom food trailer build process begins with an extensive consultation where builders assess your specific needs, menu requirements, and operational goals. During this phase, you’ll discuss your concept, target market, preferred locations, and budget constraints.

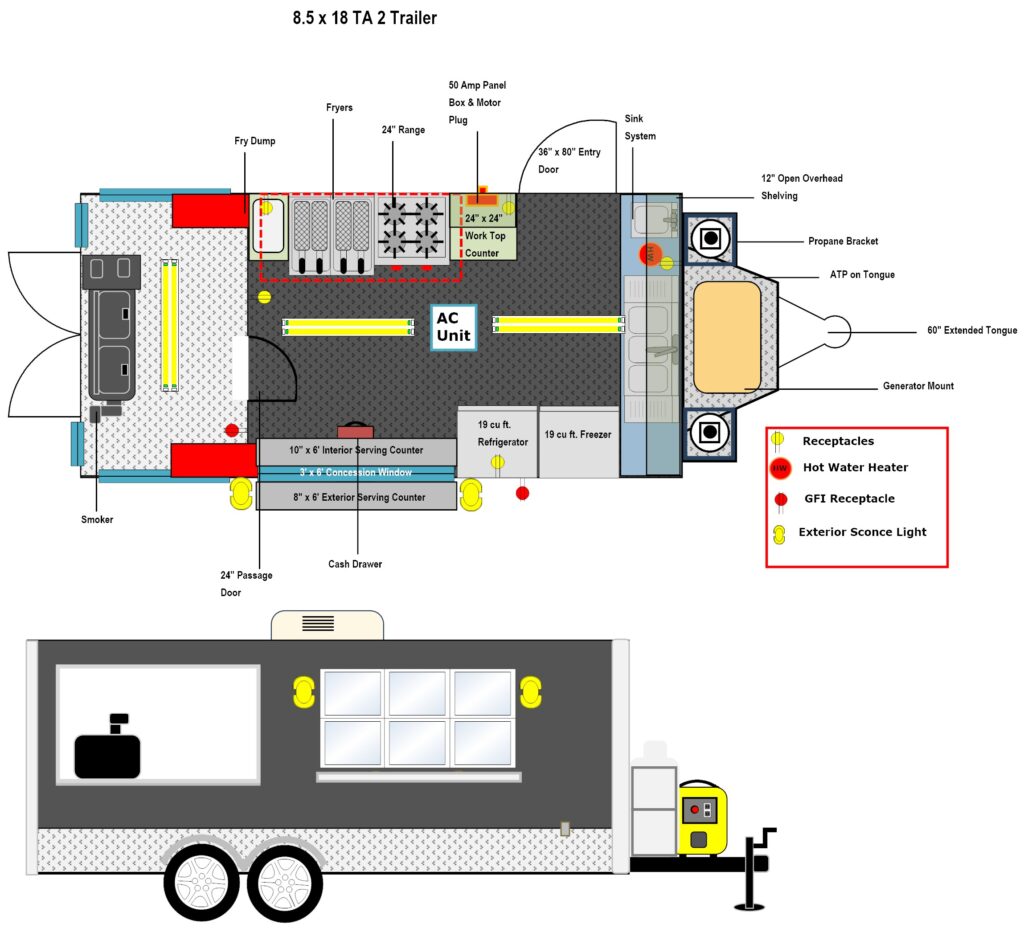

Professional builders will evaluate your menu to determine the necessary equipment, workspace layout, and utility requirements. This analysis directly influences the trailer’s size, electrical capacity, plumbing needs, and ventilation systems. food trailer construction

Design specifications include exterior aesthetics, branding elements, serving window configurations, and interior workflow optimization. Expect multiple design revisions as builders refine the layout to maximize efficiency within your budget parameters.

Regulatory Compliance and Permits

Custom food trailers must comply with local health department regulations, fire safety codes, and transportation requirements. Experienced builders understand these complex regulations and incorporate necessary features during the design phase.

Health department compliance includes proper food storage areas, handwashing stations, three-compartment sinks, and adequate ventilation systems. Fire safety requirements may mandate specific suppression systems, electrical configurations, and emergency exits.

Transportation regulations govern trailer weight distribution, lighting systems, brake configurations, and overall dimensions. Professional builders ensure your trailer meets Department of Transportation standards for safe highway travel.

Construction Timeline Expectations

Custom food trailer construction typically requires 8 to 16 weeks, depending on complexity, customization level, and builder workload. Simple builds with standard equipment may complete faster, while elaborate designs with specialized features require additional time.

The timeline includes design finalization, material procurement, fabrication, equipment installation, and final inspections. Weather conditions, supply chain delays, and change requests can extend the original schedule.

Builders should provide regular progress updates and communicate any potential delays immediately. Establishing clear milestone dates helps manage expectations and allows for proper business planning.

Structural Foundation and Framework

Quality food trailers begin with robust structural foundations designed to support heavy commercial equipment while maintaining road safety standards. The chassis selection depends on your trailer’s intended weight, equipment load, and transportation requirements.

Steel framework construction provides durability and longevity essential for commercial food service operations. Proper welding techniques and structural reinforcements ensure the trailer withstands daily operational stresses and highway transportation.

Insulation installation occurs during the framework phase, creating energy-efficient environments that reduce operational costs and maintain consistent interior temperatures. Quality insulation also minimizes condensation issues that can damage equipment and create unsanitary conditions.

Electrical System Installation

Commercial food trailers require sophisticated electrical systems capable of powering multiple high-demand appliances simultaneously. Professional installations include adequate circuit capacity, proper grounding, and safety shutoffs.

Electrical planning considers your equipment’s power requirements, peak usage scenarios, and connection options for different venues. Many trailers accommodate both generator power and shore power connections for operational flexibility.

Safety features include ground fault circuit interrupters, emergency shutoffs, and proper ventilation for electrical components. Professional electricians ensure all installations meet commercial electrical codes and local inspection requirements.

Plumbing and Water Systems

Food trailer plumbing systems include fresh water storage, wastewater collection, and hot water generation. System capacity depends on your menu requirements, expected daily volume, and local regulations.

Fresh water tanks typically range from 20 to 100 gallons, while wastewater tanks must accommodate gray water from sinks and equipment cleaning. Some jurisdictions require separate tanks for different wastewater types.

Hot water systems may include tankless heaters, traditional water heaters, or combination units that provide both heating and storage. Proper insulation and freeze protection ensure year-round operation in various climates.

Kitchen Equipment Integration

Equipment selection and installation represent significant portions of your trailer’s total cost and functionality. Professional builders help specify appropriate equipment based on your menu, expected volume, and space constraints.

Commercial-grade equipment ensures durability and performance under demanding conditions. Proper installation includes adequate ventilation, utility connections, and safety clearances required by manufacturer specifications and local codes.

Equipment placement optimization maximizes workflow efficiency while maintaining safety standards. Experienced builders understand food service operations and design layouts that minimize movement and maximize productivity.

Ventilation and Fire Suppression

Adequate ventilation systems remove heat, smoke, and cooking odors while maintaining comfortable working conditions. Commercial ventilation requirements often exceed residential standards and may include makeup air systems.

Fire suppression systems protect both equipment and personnel from cooking-related fires. Automatic suppression systems activate when detecting excessive heat or flames, immediately suppressing fires and shutting down fuel sources.

Regular maintenance and inspection of these systems ensure continued compliance and operational safety. Professional installation includes proper training on system operation and maintenance requirements.

Interior Finishing and Workflow Design

Interior finishes must withstand commercial food service demands while maintaining sanitary conditions. Non-porous surfaces, seamless installations, and easy-to-clean materials are essential for health department compliance.

Workflow design considers food preparation sequences, service patterns, and cleaning procedures. Efficient layouts minimize cross-contamination risks while maximizing productivity during peak service periods.

Storage solutions include refrigerated areas, dry storage, and equipment storage designed to maximize space utilization. Professional builders incorporate creative storage solutions that maintain organization without compromising workspace.

Exterior Design and Branding

Exterior design elements attract customers and communicate your brand identity effectively. Professional builders coordinate with graphic designers to create cohesive branding that stands out in competitive markets.

Serving window configurations balance customer service efficiency with weather protection and security. Multiple window options provide operational flexibility for different venues and weather conditions.

Exterior lighting enhances visibility and creates inviting atmospheres during evening operations. LED lighting systems provide energy efficiency and longevity while meeting transportation lighting requirements.

Quality Control and Testing

Comprehensive testing procedures verify all systems function properly before delivery. Testing includes electrical systems, plumbing operations, equipment functionality, and safety system activation.

Quality control inspections examine construction quality, finish work, and compliance with specifications. Professional builders address any deficiencies before final delivery and customer acceptance.

Documentation includes equipment manuals, warranty information, maintenance schedules, and operational procedures. Proper documentation supports ongoing maintenance and regulatory compliance throughout the trailer’s operational life.

Final Inspection and Delivery

Final inspections may include health department reviews, electrical inspections, and transportation safety checks. Professional builders coordinate these inspections and address any required modifications promptly.

Delivery includes comprehensive orientation covering equipment operation, maintenance procedures, and safety protocols. This training ensures safe operation and helps prevent costly mistakes during initial operations.

Warranty coverage typically includes structural components, electrical systems, and equipment installations. Understanding warranty terms and maintenance requirements protects your investment and ensures continued operation.

Post-Delivery Support and Maintenance

Ongoing support includes technical assistance, maintenance guidance, and repair services. Establishing relationships with qualified service providers ensures minimal downtime when issues arise.

Regular maintenance schedules preserve equipment functionality and extend operational life. Professional builders provide maintenance checklists and recommend service intervals for different components.

Many builders offer modification services as your business evolves. Menu changes, equipment upgrades, or operational improvements may require trailer modifications that experienced builders can accommodate efficiently.

The FDA Food Code provides comprehensive guidelines for mobile food operations, while the National Fire Protection Association establishes safety standards for commercial cooking operations.

Investment Considerations and Financing

Custom food trailer costs vary significantly based on size, equipment, and customization levels. Basic builds may start around $50,000, while elaborate custom designs can exceed $200,000.

Financing options include traditional business loans, equipment financing, and specialized food truck lending programs. Many builders offer financing assistance or partnerships with lending institutions familiar with mobile food businesses.

Total investment calculations should include trailer costs, permits, initial inventory, marketing, and working capital. Comprehensive financial planning ensures adequate resources for successful business launch and initial operations.

Understanding the custom food trailer build process helps entrepreneurs make informed decisions and establish realistic expectations. Professional builders provide expertise, regulatory compliance, and quality construction that supports successful mobile food operations for years to come.

No products in the cart.

No products in the cart.